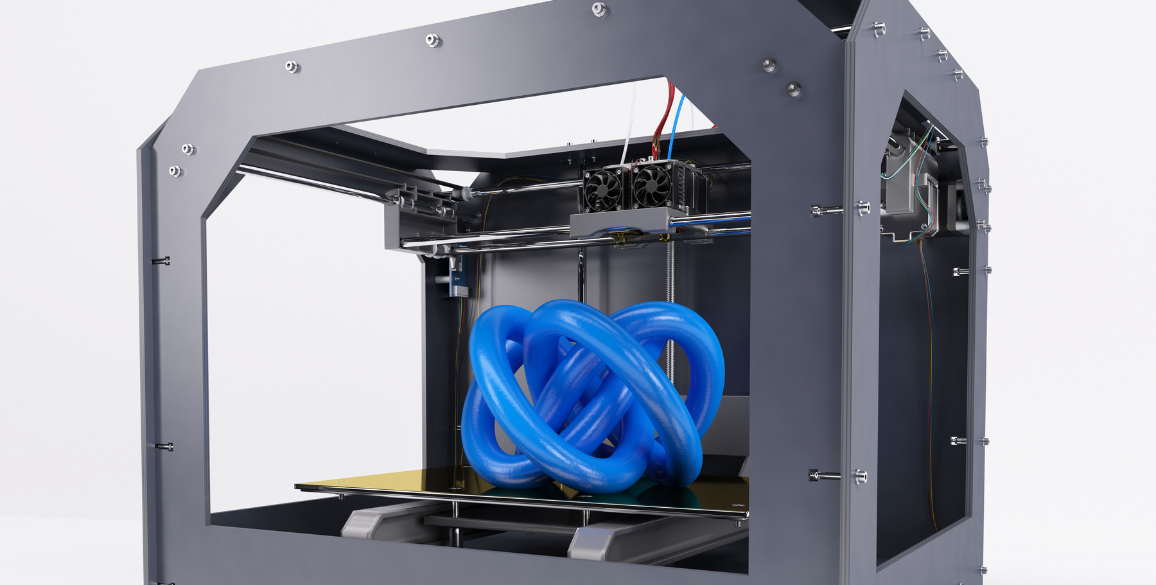

How to Start a 3D Printing Business?

The 3D printing scene in India is growing fast because more people want quick prototypes (early models used to test ideas) and custom products. According to Fortune Business Insight, the global market is expected to hit $48.94 billion (around ₹4.1 lakh crore) by 2030, and India is growing at over 20% every year. Companies like Mahindra are using 3D printing to make car parts much faster, cutting production from weeks down to days.

A great example is Imaginarium from Mumbai. They started small but now work with big names like Bajaj Auto and Tata Motors, handling everything from prototypes to final parts. This guide will help you turn your skills and ideas into a successful 3D printing business.

How to Start a 3D Printing Business in India: 9-Step Process

Follow these proven steps to launch your successful 3D printing business in the Indian market:

Step 1: Define Your 3D Printing Niche and Target Market

Choose one primary 3D printing category to focus your efforts effectively. Popular 3D printing business ideas include:

- Rapid Prototyping: Creating quick iterations of product designs for various industries (automotive, electronics, consumer goods).

- Custom Parts & Manufacturing: Producing specialized components, jigs, fixtures, or low-volume production runs.

- Architectural Models: Developing scaled models for real estate, urban planning, and construction.

- Figurines & Collectibles: Manufacturing custom action figures, miniatures, or unique art pieces.

- Jewelry & Fashion Accessories: Producing intricate designs for bespoke jewelry or fashion components.

- Medical & Dental Models: Creating anatomical models for surgical planning or custom dental aligners.

- Educational Tools: Developing interactive models for schools, universities, and training centers.

- Spare Parts: Manufacturing obsolete or hard-to-find replacement parts.

Before diving into marketing or purchasing equipment, you need to understand what your local audience truly needs. This begins with focused, practical market research.

a. Market Research:

- Look into what local industries need by talking to manufacturers, design studios, and schools.

- Analyze what competing 3D printing services charge, their work quality, and delivery times.

- Survey potential clients to understand their specific needs for 3D printed items, materials, and finishes.

b. Location Factors:

- Big cities (Metro cities) often prefer high-precision, industrial prints, advanced materials, and rapid prototyping for research and development (R&D).

- Smaller cities (Tier-2 cities) might have demand for everyday prints, learning models, small-batch manufacturing, and affordable custom solutions.

- Tier-3 cities and towns demand affordable 3D printing for local repairs, student projects, and small business prototyping, with a focus on services over industry and support from education or training centers.

Note: Logistics for material delivery and printer servicing can delay operations—plan buffer time accordingly, especially in Tier-2 and Tier-3 cities where access may be slower.

Step 2: Create Your 3D Printing Business Plan

Develop a detailed plan covering your vision, mission, and specific goals for at least 3 years. Include descriptions of your ideal customers, noting their industry, project needs, and budget.

a. Money Planning:

- Estimate startup costs for a home-based or small workshop 3D printing business around Rs. 2 Lakh - Rs. 10 Lakh, depending on printer choice.

- Project monthly costs, including materials, software licenses, electricity, machine upkeep, and marketing.

- Plan for fluctuating demand by keeping extra materials ready and considering service agreements for steady income.

- Include costs for tools used after printing, like curing stations, sanding tools, and painting supplies.

Step 3: Choose How Your 3D Printing Business Model

Select the way your business will operate that best matches your skills, resources, and long-term goals.

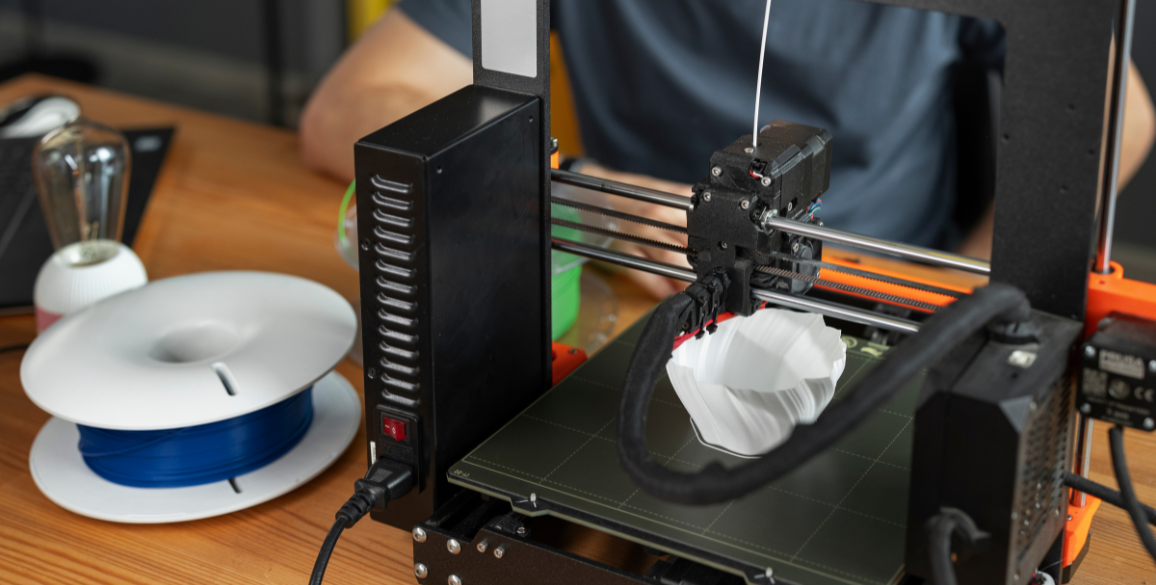

1. Home-Based 3D Printing Business

Start a successful 3D printing business from your home with relatively low initial cost, especially if you use Fused Deposition Modeling (FDM) or resin printers. This model works well for custom orders, making models for local businesses, and creating special consumer products. It offers good profits with low running costs.

What You'll Need:

- A dedicated workspace with good airflow, especially for resin printers.

- A stable power supply and a controlled environment (right temperature, no dust).

- Basic Computer-Aided Design (CAD) software and slicing tools.

- An area for finishing prints.

2. Online 3D Printing Service

Set up your 3D printing business online through platforms like Shapeways, Sculpteo, or your e-commerce website. This model lets you reach customers all over the country and globally, and offers growth potential.

Popular Online Places:

- think3D/Imaginarium: Commission-based sales; they handle manufacturing and shipping.

- Your Website: Costs Rs. 10,000 to Rs. 30,000 per year for hosting and domain. You set prices and talk directly to customers.

- IndiaMart/TradeIndia: Business-to-Business (B2B) websites for service listings.

- Social Media (Instagram/LinkedIn): Show off complex prints and connect with potential clients.

3. Partnering with Retailers

Work with local design studios, engineering companies, architectural firms, or gift shops to offer your 3D printing services. This provides steady sales and helps your brand become known locally.

Ways to Partner:

- Service Agreements: Provide ongoing model-making or custom part manufacturing.

- Consignment Deals: Sell unique 3D printed products in local boutiques.

- Collaborations: Work with designers to bring their ideas to life.

- Participating in Fairs/Exhibitions: Show what you can do at industry events, costing Rs. 1,000 to Rs. 5,000 per event.

4. Workshop and Teaching Model

Combine selling 3D printed products with offering classes and workshops. This adds more ways to earn money and establishes you as a local 3D printing expert.

Teaching Opportunities:

- Private Lessons: Charge Rs. 1,000 to Rs. 3,000 per hour for teaching software or printer use.

- Group Workshops: Charge Rs. 800 to Rs. 2,000 per person for 4-8 hours on basic 3D printing.

- Online Courses: Charge Rs. 3,000 to Rs. 10,000 for a complete course on specific software or applications.

- Company Training: Charge Rs. 20,000 to Rs. 50,000 per session for special training for businesses.

Step 4: Handle Legal Needs and Licenses

Get all necessary legal papers sorted correctly for your 3D printing business in India.

a. Business Registration

Choose the legal structure for your business based on its size and growth plans. Register as a:

- Sole Proprietorship (Rs. 500- Rs. 2,000)

- A Private Limited Company (Rs. 12,000- Rs. 18,000).

Documents Needed:

- Permanent Account Number (PAN) card, Aadhaar card, and proof of your current address.

- Bank account statements and passport-sized photographs.

- Property documents or a rental agreement for your business address.

b. Trade License and Permits

Get a Trade License from your local Municipal Corporation (this might cost Rs. 1,000- Rs. 5,000 yearly) to operate within city limits.

c. Goods and Services Tax (GST) Registration for 3D Printing Business

In India, if your total yearly sales go over Rs. 20 lakhs (or Rs. 10 lakhs in special states), you must register for GST . Services related to 3D printing might fall under the 18% GST category.

Benefits of GST Registration:

- Following the law for business growth.

- Getting back tax paid on raw materials, equipment, and software.

- Increased trust with Business-to-Business (B2B) customers and larger companies.

Step 5: Get Money for Your 3D Printing Business

Understand how much money you need and what funding options are available.

Here’s a practical estimate of initial and ongoing costs to help you budget smartly.

a. One-Time Setup Costs:

- 3D Printer(s):

-

- Basic FDM/Resin: Rs. 50,000–Rs. 2,00,000

- Mid-range Industrial/Prototyping: Rs. 2,00,000–Rs. 10,00,000+ (Metal 3D printers can range from Rs. 10 Lakh to Rs. 3 Crore+)

- Software Licenses (CAD, Slicing, Mesh Repair): Rs. 10,000–Rs. 50,000 (annual or one-time fee). Specialized software like Materialise Magics can cost more than Rs. 2.5 Lakh.

- Post-processing Equipment: (Tools for finishing prints like curing stations, washing stations, sanding tools, safety gear, painting supplies): Rs. 10,000–Rs. 50,000

- Workstation/Computer: Rs. 30,000–Rs. 1,00,000 (must be powerful enough for design files)

- Initial Material Stock: Rs. 20,000–Rs. 50,000 (various filaments, resins, powders like PLA, ABS, PETG, typically costing Rs. 500-Rs. 5,500 per kilogram)

- Storage Solutions: Rs. 5,000–Rs. 15,000 (for materials and finished prints)

Total for Equipment and Tools: Rs. 1,25,000–Rs. 12,65,000

b. Ongoing Costs (First 6 Months):

- Raw Materials Refill: Rs. 10,000–Rs. 40,000/month (depends on print volume)

- Printer Upkeep & Spare Parts: Rs. 2,000–Rs. 10,000/month

- Marketing and Promotion: Rs. 5,000–Rs. 20,000/month

- Electricity Costs: Rs. 3,000–Rs. 10,000/month (depends on printer usage)

- Software Subscriptions: Rs. 1,000–Rs. 5,000/month

Tip: Start with a versatile, reliable printer. Expand your machines and technology as demand grows. Reinvest profits to upgrade equipment and capabilities.

Government Funding Options:

- Mudra Loans: Registering as an MSME (Micro, Small & Medium Enterprise) helps you get working capital loans at lower interest rates and government subsidies. For eg, IDBI (Small Industries Development Bank of India) is an excellent funding partner for MSMEs in tech.

- Stand-Up India Scheme: Women entrepreneurs and Scheduled Castes (SC)/Scheduled Tribes (ST) entrepreneurs can get loans between Rs. 10 lakhs to Rs. 1 crore. The bank funds 75% of the loan, with a 25% personal contribution, if registered under Startup India .

Step 6: Find Good Quality Materials and Suppliers

Build trustworthy supply chains for consistent quality and cost management.

a. Finding Bulk Material Suppliers:

- Source filaments (PLA, ABS, PETG), resins (standard, dental, engineering), and powders (nylon, metals) based on your 3D printing needs.

- Attend trade shows and industry expos to connect with trusted suppliers and explore bulk deals.

- Partner with Indian suppliers like WOL3D, Divide by Zero, or Protomont for faster delivery and better local support.

b. Main Supplier Types:

- Local Dealers: For common filaments and resins (e.g., online stores like Amazon, local electronics shops).

- Specialized Material Makers: For stronger engineering-grade materials, biocompatible resins, or metal powders.

- Online Bulk Platforms: IndiaMart, TradeIndia for larger orders.

- International Suppliers: Through websites like Alibaba for special or bulk materials.

Checking Quality:

- Test material quality (diameter consistency, how it handles heat, strength) before buying large amounts.

- Store materials correctly to prevent damage (e.g., keep filaments dry to avoid moisture).

- Calibrate printers regularly for accurate, quality prints with different materials.

- Keep records of material details and batch numbers for easy tracing.

Step 7: Create a Strong Brand for Your 3D Printing Business

Develop a brand that people will remember and trust, showing your technical skill, new ideas, and appealing to your perfect customers.

a. Brand Name & Visual Look:

Choose a brand name that fits your 3D printing specialty and tech focus. Make it easy to say, spell, and remember. Consider getting a trademark registration for your brand name to protect it legally.

b. Key Brand Parts:

- Design a modern, tech-focused logo for your website, business cards, and even printed products.

- Choose colors that work well together and show precision, innovation, and reliability.

- Keep your online presence, packaging (if you use it), and communication consistent.

- Write an engaging story about your brand, highlighting your passion for 3D printing and commitment to quality.

c. Defining Your Products/Services:

- Create a range of services showing your unique abilities and the types of materials/printers you specialize in. Offer a mix of services at different price levels to meet various client needs.

d. Service/Product Types to Consider:

- Basic Services: Simple FDM printing for hobbyists or small functional parts.

- Mid-range Offers: Stereolithography (SLA) or resin printing for detailed models and custom figures.

- High-end Services: Industrial-grade printing (like Selective Laser Sintering (SLS) or Direct Metal Laser Sintering (DMLS)) for advanced manufacturing and special materials.

- Design & Advice: Offering 3D modeling services, print optimization, or material selection advice.

- Batch Production: Offering competitive pricing for small to medium-sized production runs.

A consistent look and feel across your services, communication, and printed samples helps build long-term customer loyalty.

Step 8: Set Up Your Sales & Marketing Channels

Reach more customers by combining online visibility with local industry engagement.

a. Build a Professional Online Presence:

- Create an online space where potential customers can explore your 3D printing capabilities, view your past work, and ask for quotes.

- Use visual platforms like LinkedIn, Instagram, and specialized industry forums to show off your work and build a professional network.

b. Network Within Your Local Community:

- Increase your visibility and trustworthiness by making local connections and joining industry events.

- Engaging with businesses in your area can lead to valuable partnerships and steady projects.

Mixing online strategies with local outreach ensures a balanced and growing path for your 3D printing business.

Step 9: Launch and Grow Your 3D Printing Business

Start strategically and expand gradually based on market response and production capacity.

Soft Launch Strategy: Begin by offering a small range of services or focusing on a specific niche to friends, family, and a few local businesses. Use their initial feedback to improve service quality, pricing, and delivery times.

Testing Phase:

- Start with 2-3 main services (e.g., FDM prototyping, resin models).

- Focus on making print quality and consistency perfect.

- Collect detailed feedback from every client.

- Adjust designs and prices based on market needs.

Growing Your Operations:

- Expand your service range and reach more customers based on demand and operational efficiency.

Growth Strategies:

- Add related services (e.g., advanced post-processing, 3D scanning, design services).

- Increase production capacity by buying more printers or advanced technologies (e.g., metal 3D printing).

- Expand to new sales channels and target new industries.

- Consider offering online courses or consulting services for extra income.

Focus on consistent quality, delivering on time, and providing excellent customer service. Build a strong reputation through successful projects, positive reviews, and word-of-mouth recommendations.

Why You Should Start a 3D Printing Business in India?

Discover why starting a 3D printing business offers unique advantages for entrepreneurs who love technology:

- Growing Market: India’s 3D printing market is growing fast, from USD 61.4 million in 2023 to an expected USD 314 million by 2030. Rising demand makes it a strong business opportunity.

- New Ideas & Customization: Offer highly customized solutions and help with quick new ideas across different industries, meeting unique client needs.

- Many Uses (Versatile Applications): This technology can be used in many areas like healthcare, cars, aerospace, and everyday consumer goods, giving you various ways to earn money.

- Easier to Start (for desktop systems): You can begin with affordable desktop 3D printers and grow your business as demand increases.

- Creative and Technical Satisfaction: Combine your technical skills with a passion for design and solving problems, turning digital ideas into real objects.

Get Your Company Registered Today

Free consultations for MCA approvals to help you get started with your business.

Challenges and Common Issues in 3D Printing Business

Understanding potential difficulties helps you prepare better plans for success.

- High Starting Cost: Professional-grade 3D printers and special software can be very expensive.

-

- Solution: Begin with reliable, entry-level printers. Reinvest profits for upgrades. Look into renting or financing options.

- Needs Technical Skills: Operating, maintaining, and fixing 3D printers, along with using design software, requires specific knowledge.

-

- Solution: Invest in training, constantly update your knowledge, and build a network of experts for help.

- Material Costs: Special filaments, resins, and powders can be expensive, which affects how much profit you make.

-

- Solution: Buy from bulk suppliers, optimize print settings to reduce wasted material, and set prices competitively to cover costs.

- Time for Finishing Work: Many printed items need a lot of finishing (like sanding, curing, painting), which adds to production time.

-

- Solution: Make your work process more efficient, buy tools for faster finishing, and include finishing time in your project timelines and pricing.

- Competition: You'll face tough competition from existing service providers and larger industrial companies.

-

- Solution: Specialize in a particular area, offer excellent customer service, faster delivery times, or unique material/technology capabilities.

- Intellectual Property Concerns: Handling client designs means you need to be careful about ownership rights.

-

- Solution: Use clear Non-Disclosure Agreements (NDAs) and strong data security measures.

How Can You Make Your 3D Printing Business a Big Success?

Proven strategies to help your 3D printing business thrive in competitive markets.

- Perfect Your Craft: Continuously improve your 3D modeling skills, printing methods, and knowledge of materials. Stay updated with new technologies and industry trends.

- Document Everything: Keep detailed records of printer settings, material profiles, client project details, and successful print settings for consistent quality and easy repetition.

- Build Client Relationships: Keep communication with clients strong and clear, provide excellent service, and understand their changing needs.

- Price Smartly: Research market rates, accurately calculate costs for materials, printing time, and finishing work, and set your prices to make a profit while still attracting customers.

- Professional Presentation: Invest in high-quality photos and videos of your printed parts, create professional examples of your work (case studies), and ensure your online presence looks polished.

- Follow Up After Service: Contact clients after their project is done to ensure they are happy, gather feedback, and encourage them to use your services again or recommend you to others.

- Invest in Research and Development (R&D): Continuously try out new materials, printing techniques, and uses to offer cutting-edge solutions and stay ahead of the competition.

Get Your Company Registered Today

Free consultations for MCA approvals to help you get started with your business.

Frequently Asked Questions (FAQs)

What are the basic requirements to start a 3D printing business?

−You’ll need a 3D printer, CAD software, raw materials (like PLA or ABS filament), a reliable computer, and basic designing or engineering skills. A workspace and business registration are also important.

Do I need technical knowledge to start a 3D printing business?

+What is the initial investment for a 3D printing business in India?

+Which 3D printing niches are most profitable?

+How do I get clients for my 3D printing services?

+What licenses or permissions are needed in India for a 3D printing business?

+Is 3D printing environmentally sustainable?

+Can I run a 3D printing business from home?

+